JetFoam™ - Automated High-Throughput Defoamer and Antifoamer Performance Analyzer

Quantitative defoamer testing — from screening through optimization — fully automated, fully reproducible, and fast enough to keep up with real formulation decisions

Selecting a defoamer is rarely straightforward. The chemistry of defoaming is complex — silicone oils, mineral oils, polyglycols, particles, and blended systems all work through different mechanisms, and their effectiveness depends not only on their own chemistry but also on the foaming system to which they are added. A defoamer that performs well in one formulation may be ineffective or even counterproductive in another. Concentration, timing, and temperature matter. The only reliable way to find the right defoamer at the right dose for a specific application is to test it — and in most real-world formulation programs, that means testing many candidates at multiple concentrations under controlled conditions.

This is where conventional testing methods break down. Manually generating foam, adding a defoamer, and visually judging the result is slow, subjective, and difficult to reproduce from one experiment to the next. Different operators will generate foam differently, add the defoamer at different points, and interpret the result differently. When the question is not just whether a defoamer works but how well it works, how quickly it acts, how long the effect persists, and how it compares quantitatively to every other candidate on the table, visual observation and manual methods cannot provide the answers at the speed or reliability that formulation decisions require.

The JetFoam is the only commercial instrument designed specifically and exclusively for quantitative defoamer and antifoamer performance testing. It automates the entire measurement sequence — foam generation, defoamer injection, foam volume measurement, stability monitoring, and system cleaning — with the precision and reproducibility needed to make meaningful comparisons between candidates. A single automated run can evaluate up to 28 defoamer samples sequentially, without operator intervention, producing quantitative data for each.

How It Works

The JetFoam generates foam by directing a high-velocity liquid jet into a pool of the foaming solution inside a glass measurement column. This jet-circulation method rapidly and reproducibly produces foam, with the flow rate and duration precisely controlled by the software. The foam volume is measured continuously by a video camera and image analysis system that tracks the foam height inside the column throughout the experiment.

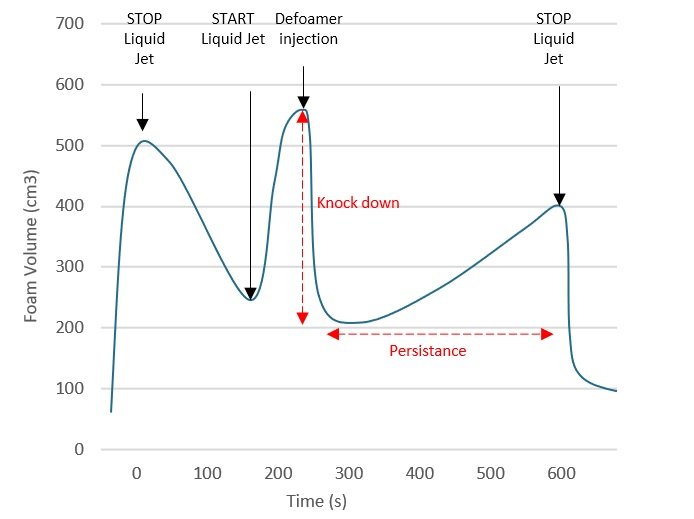

A typical measurement sequence proceeds as follows. The liquid jet generates foam for a defined period, and the resulting foam volume is recorded — this is the baseline foamability of the solution. The jet is then stopped, and foam stability is measured as the foam decays. The jet restarts, and at a predetermined time or foam volume, the defoamer is automatically injected into the system. The foam response is then measured: how quickly the foam collapses after defoamer addition (the knockdown effect), how much foam volume is eliminated, and how long the defoaming effect persists before the foam begins to recover. These three quantities — effectiveness, knockdown speed, and persistence — are the essential performance metrics for any defoamer evaluation, and the JetFoam measures all of them quantitatively, from the same experiment, under identical conditions for every sample tested.

The software controls every parameter in the sequence: liquid volume, jet flow rate, foaming duration, defoamer injection timing and volume, measurement intervals, and cleaning cycles. Once the run is programmed, the instrument executes it identically for every sample — eliminating the operator variability that makes manual defoamer testing unreliable.

JetFoam Full Defoamer Testing Cycle Measurement View

Complete Automation and High Throughput

The JetFoam is a Fully Automated High Throughput Defoamer Efficiency and Efficacy Testing Instrument

The JetFoam is a fully automated system. It collects defoamer samples from a carousel holding up to 28 vials, injects each sample at the programmed point in the measurement sequence, measures the foam response, and then cleans the entire liquid pathway—column, tubing, and jet circuit—before proceeding to the next sample. The cleaning sequence can use the sample liquid itself, water, or a dedicated cleaning solution, and it runs automatically between every measurement to prevent cross-contamination from one defoamer to the next.

This level of automation is not a convenience feature. It is what makes high-throughput defoamer screening practical. Evaluating 28 defoamer candidates at a single concentration — or a smaller number of candidates at multiple concentrations — would require days of manual work with conventional methods, assuming the results were reproducible at all. The JetFoam completes the same evaluation in a single automated session, with every sample tested under identical conditions and every result directly comparable.

Experiments can be performed at temperatures up to 90°C, which is relevant for applications where defoamer performance must be evaluated at process temperature rather than at ambient conditions.

Applications

The defoamer and antifoamer market spans virtually every industry where foaming creates a processing problem. The JetFoam serves any application where quantitative defoamer selection, dosing optimization, or quality control testing is needed:

Pulp and paper — foam control during pulping, washing, and papermaking processes, where defoamer selection and dosing directly affect process efficiency and product quality.

Paints, coatings, and inks — preventing foam defects in coating formulations, where the defoamer must suppress foam without affecting surface appearance, leveling, or adhesion.

Industrial wastewater treatment — maintaining foam control in aeration basins and treatment processes, where changing influent chemistry requires ongoing defoamer optimization.

Food and beverage processing — controlling foam during cooking, mixing, fermentation, and filling operations, where the defoamer must be effective and food-safe at process temperatures.

Home and personal care — optimizing defoamer and antifoam performance in detergent, cleaning, and personal care formulations, where foam control must be balanced against product performance.

Petroleum and fuels — suppressing foam in crude oil processing, fuel handling, and lubrication systems, where persistent foaming can cause equipment problems and processing delays.

The JetFoam does not replace the FOAMSCAN — it serves a different purpose. The FOAMSCAN is designed to characterize foam behavior, including foamability, stability, drainage, liquid fraction, and bubble-size evolution.

The JetFoam is designed to answer a different question: which defoamer works best for your specific foaming system, at what concentration, and for how long. It is a formulation tool built for speed, throughput, and direct quantitative comparison — the kind of instrument that turns defoamer selection from an art into a measurement.

If you are evaluating defoamers or antifoamers and want to see how the JetFoam can accelerate your testing program, we would welcome the conversation.