FoamScan™ - Measure Precisely. Formulate Confidently.

Understand your liquid foams from A to Z.

Foams are ubiquitous. Foams are complex. Foams can be good, foams can be bad.

To understand foam behavior correctly, you need to capture and analyze its formation, life, and decay.

Liquid foam is a gas phase dispersed into a liquid phase. Foams do not form spontaneously, and energy is required to generate foams.

Foam behavior is governed by its vast interfacial area and thermodynamic instability. These two factors make foams inherently unstable.

While foams spontaneously destruct (leading to the eventual foam collapse), the rate at which foam instability occurs can vary widely from seconds and minutes to days, weeks, or more.

Depending on your applications, foams can be good or bad.

When foam generation is the objective, we want a solution with high foamability, large foam-to-liquid volume values, and very stable foam.

When foam generation is undesirable, we want a solution with lower foamability, low foam volume, and a quick foam decay mechanism leading to a complete foam collapse.

To fully understand foam stability and dynamics, it may be helpful to think of foams as having a lifecycle:

1) foam generation

2) foam equilibration

3) foam decay, and finally

4) foam collapse.

In other words, for complete foam characterization, we need to be able to capture and analyze the foam’s macro and micro dynamics and associated physicochemical properties across the entire lifespan.

“The FoamScan instrument has also proved useful in antifoaming/defoaming studies.”

— Bubble and Foam Chemistry, Professor Robert J. Pugh, Cambridge University Press, 2016

Foam Formation, Life, and Decay

to understand foam behavior you need to capture and analyze its birth, life, and death

If you want to characterize and understand foam correctly, you must have the freedom to

generate foams using different techniques and conditions

perform dynamic and static foam stability analysis

analyze both foam macro and micro-properties

do so under wide-ranging environmental conditions

Foam Analysis using the Multiscale Characterization Principle

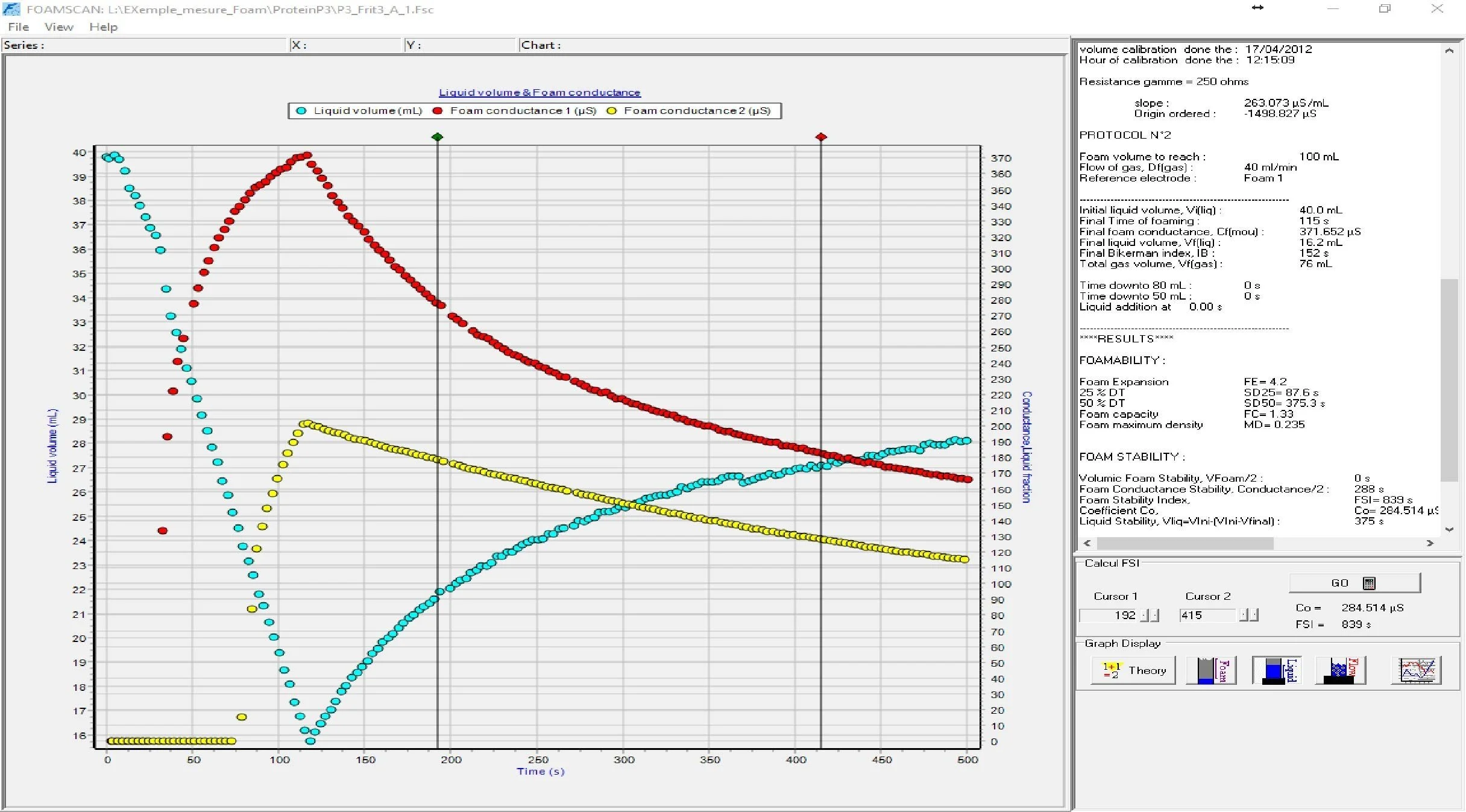

The FoamScan™ Multiscale Characterization Principle (MCP) enables you to capture and analyze macro and micro events over the entire foam lifespan.

The FoamScan™ design strategically places multiple probes and cameras so you can capture foam macro-properties (e.g., foam capacity, foam expansion, foam drainage, foam decay, liquid volume, liquid fraction, foam density, Foam Stability Index, Bikerman Index, etc.) and foam micro-properties (e.g., foam cell size, foam bubble size, size distribution, coalescence, Ostwald ripening) across the entire column height.

The combination of macro and micro-foam analysis during each foam’s life cycle (birth, life, death) is essential for a complete picture of your foam's characteristics and behavior.

Multiple Foam Generation Modes

The means of foam generation can also influence foam stability. The FoamScan™ allows you to generate foams using three different methods:

gas injection at various flow rates and different bubble sizes

mechanical stirring at different RPM/shear rates

external foam generation of your choice

Foam Macro-Dynamics

The FoamScan™ allows you to obtain all relevant macro-foam generation and stability events along the entire foam column :

Liquid volume

Foam volume

Foam density

Foam stability

Liquid fraction (liquid drainage)

Bikerman Index

Foam Capacity

Expansion Coefficient

Conductance

Foam maximum density

Foam Stability Index

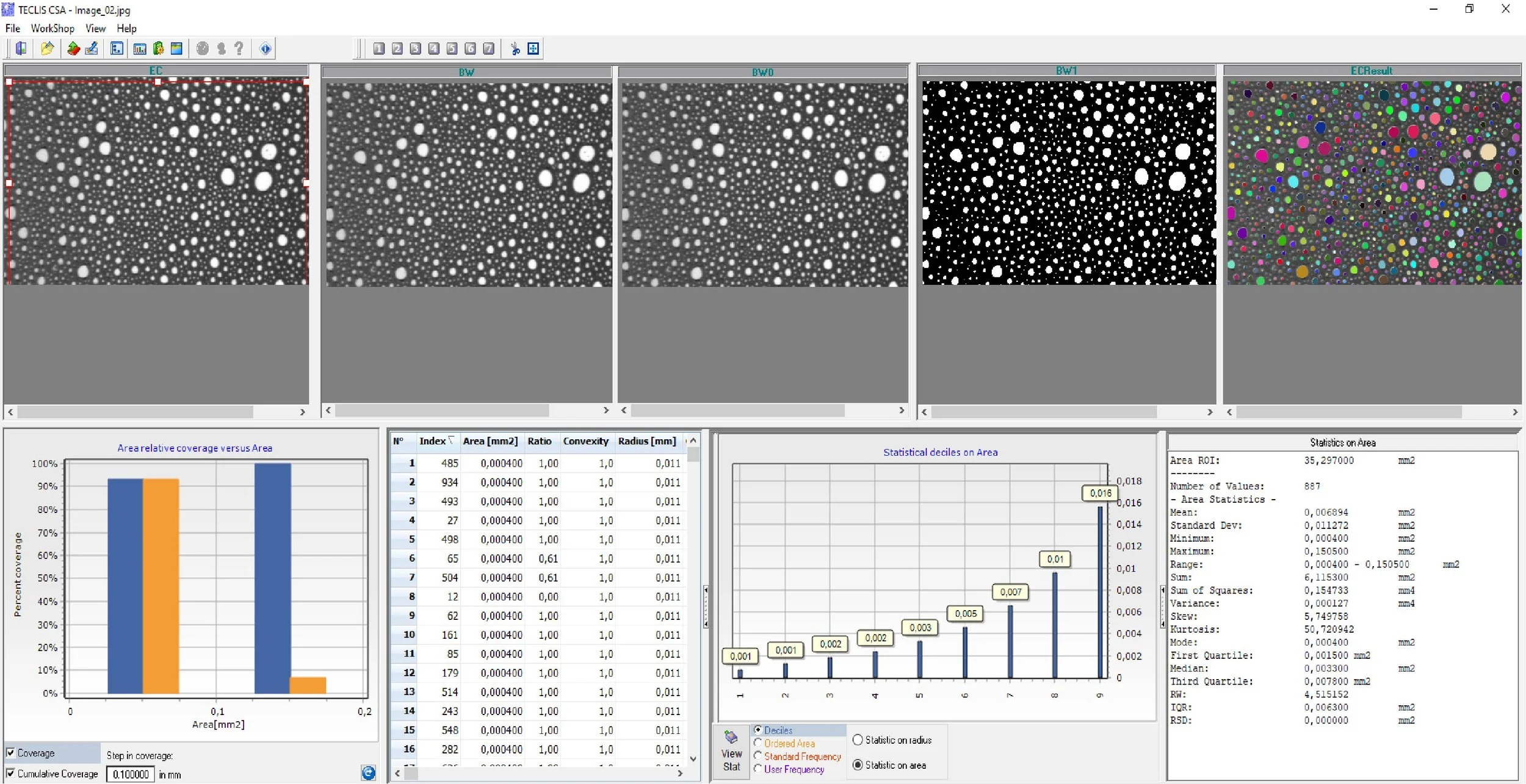

Foam Cell Size and Bubble Particle Size Analysis

The Cell Size Analysis (CSA) software allows you to measure cell and bubble size distributions and monitor their changes over time.

You can see the effect of different foam generation techniques on bubble size and its correlation to foam stability. You will also be able to discern the various pathways of foam destruction (Ostwald ripening, coalescence, etc.).

This micro-analysis capability will give you unique additional insight into foam behavior.

Complete Foam Analysis at Elevated Temperatures and Pressures

With the standard medium temperature and pressure module, you can analyze foams up to 120°C (248°F) and 8 bars (116 psi).

If you need higher pressures and temperatures, please have a look at our high-pressure and temperature model (HTHP).

With one instrument, you can understand all relevant foam properties.

The FoamScan™ allows you to understand the variables that go into foam generation and decay. Both on a macro and micro scale.

In other words, you can capture and analyze the foam’s birth, life, and death

This is not meant as an empty marketing slogan but is based on years of research and scientific facts.

FoamScan™ - your complete foam analyzer.