JetFoam™ Defoamer Performance Analyzer - Measure Precisely. Formulate Confidently.

Precisely measure the effectiveness of defoamers with the fully automated high-throughput defoamer and antifoamer JetFoam™ analyzer

While Foams are thermodynamically unstable, they may persist over long periods. For many industrial processes (e.g., pulp and paper, crude oil, fuels, lubrication, pharmaceutical, food, beverages, etc.), this can cause problems.

A class of artificial and nature-based chemicals referred to as defoamers and antifoamers (antifoams) exist to combat foaming and foams. Generally speaking, defoamers are added to an existing foam aiming to destroy it by breaking the foam structure (foam breakers). Antifoamers (antifoams) are added to the solution/mixture apriori to prevent foaming (foam inhibitors).

Most antifoamers or defoamers are surface-active compounds and oils (e.g., silicone oils) that destabilize foams by spreading or forming droplets on the foam lamellas. Charge neutralization and the addition of particles are also effective defoaming methods.

While a broad range of antifoaming chemicals is available, the practical application of defoamers and antifoamers can be challenging due to the myriad of changing ingredient and processing variables in large-scale industrial applications.

Small impurities in the foaming solution or slight changes in mixing or temperature can create significant differences in foaming and the antifoaming and defoaming efficiency.

Therefore, the operator must have the means to test various concentrations and different types of antifoaming chemicals quickly to determine the optimal dosing.

The JetFoam™ was designed with this purpose in mind - to allow the operator to test antifoamers’ and defoamers’ performance and efficiencies quickly and accurately.

The JetFoam™ is a turnkey, fully automated, high throughput, self-contained defoamer, and antifoamer analyzer.

JetFoam™ Analyzer

The JetFoam™ was designed to measure the efficiency and effectiveness of defoaming and antifoaming agents. The foams are generated using liquid jet circulation and analyzed using image analysis.

The fully automated JetFoam™ is the most efficient high throughput defoamer testing equipment anywhere. The Jetfoam™ automatically

controls experimental parameters

collects and injects up to 28 defoamer samples

measures foam volumes

cleans the whole system after testing.

A video camera views foam in the glass tube, providing data to image analysis software which determines foam volume before and after defoamer injection to measure their effectiveness and persistence.

Fully Automated = Best in-class testing accuracy, reproducibility, and efficiency

The JetFoam™ is a fully automated defoamer test system and package, giving you unprecedented testing speed and efficiency.

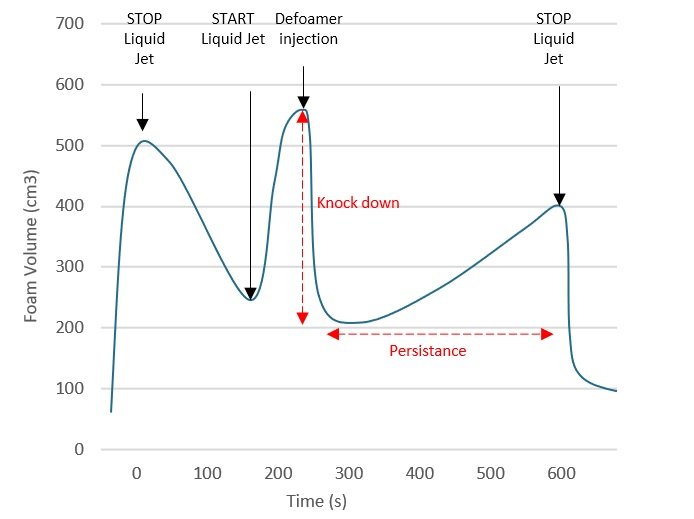

The JetFoam™ produces foam by directing a stream (jet) of problem liquid into a pool of that liquid. A video camera in the instrument views the liquid and foam inside a glass tube. The software calculates foam volume from video images and displays foam volume versus time. A typical measurement sequence is shown in the graph to the left.

The foam is produced by liquid jet circulation for a user-defined period, and the generated foam volume is measured (START).

The flow is then stopped, and the foam stability is measured (STOP Liquid Jet).

The liquid jet is started again.

The defoamer is injected at a predetermined time or foam volume, and the foam stability (foam knockdown and foam persistence) is measured.

At a user-defined time or foam volume, the chosen time, or when the expected foam volume is reached, the measurement is stopped.

After a measurement is finished, JetFoam™ begins the cleaning routine chosen, rinsing with the sample, water, or a cleaning mixture to eliminate any trace of defoamer before the subsequent measurement is made.

Experiments can be performed at temperatures up to 90 °C.